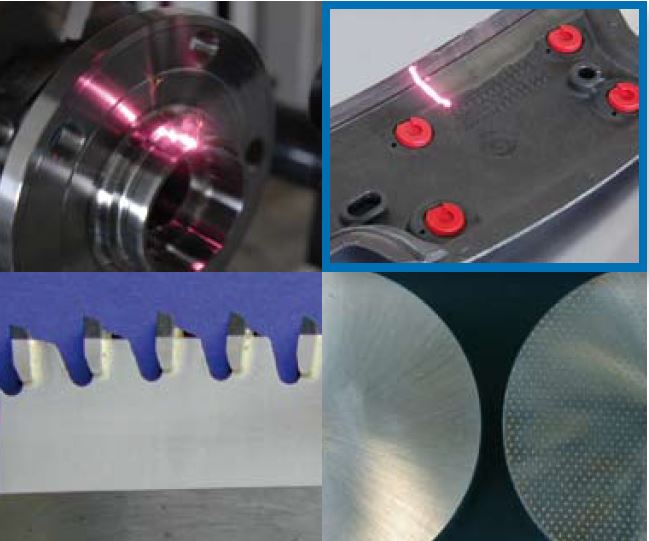

Surface Cleaning

The cleanLASER System emits ultra short laser pulses and removes soil and contamination layers without degrading or thermally damaging the substrate. Laser and beam deflection parameters are adjustable and can be easily adapted to the part’s geometry. You can choose to clean either large areas or specific portions of a part. The precise laser process offers an efficient method for state of the art ecological and economical industrial cleaning of metal substrates.

The cleanLASER System emits ultra short laser pulses and removes soil and contamination layers without degrading or thermally damaging the substrate. Laser and beam deflection parameters are adjustable and can be easily adapted to the part’s geometry. You can choose to clean either large areas or specific portions of a part. The precise laser process offers an efficient method for state of the art ecological and economical industrial cleaning of metal substrates.

Depending on the laser appliance’s average power, aluminum pre-treatment can be achieved with up to 15 cm²/minute. Aluminum and magnesium parts are excellent candidates for laser pretreatment for adhesive bonding. Other metals can also easily be cleaned and de-oiled for painting, bonding as well as other processes.

When cleaning a metal surface the oxide layer is removed, enabling a direct bond to the substrate to be achieved, which is imperative for long-term durability. The laser provides a benchmark in technology in terms of quality and cost, with excellent and scientifically proven long-term bonding stability.

Benefits:

Excellent results on metallic substrates, especially on aluminum and magnesium

Excellent results on metallic substrates, especially on aluminum and magnesium- Weld seam preparation – up to 5 m/minute

- Adhesive bonding preparation – up to 15 cm²/second

- Long-term stability for adhesive bonding

- Cleaning method free of blast media

- Process monitoring makes results highly repeatable

Do not hesitate to contact us for more information about laser cleaning.

Comments are closed.