References.

Robotic Workstation for Laser Paper Cutting

Replacement of part cutting with an oscillating knife. Laser technology allows thousands of hours of operation with minimal maintenance and is completely contactless. Multifunctional workstation concept enabling simple reprogramming of the production of other models.

Automated Workstation for 3D Laser Decoating

Automated workstation removes a thin metal layer using laser from 3D metallized plastic structures of car headlights without the need for operator intervention with 100% verification of the quality of the laser process according to the required parameters and accuracy in hundredths of a mm.

Robotic Workstation for Laser Cutting and Drilling

Integration of a unique 3D laser process into automated production. Process consists of circumferential cutting of the overlapping view foil after pressing the part with a static laser and subsequent drilling of the foil to pass the mounting holes and inside the part by means of a 3D scanning head.

Laser Cleaning of Large Format Molds

Mobile cleaning laser Spyre 500W with a customized attachment for a balancer and a "roller" with castors for easier handling on the mold surface as a replacement for cleaning with chemicals and dry ice. The customer is able to clean 2x more molds per shift with only one operator.

Large Format 3D Decoating

The aim of the project was to create defined and precisely removed metal layers in a defined pattern. Laser technology removes the metal layer without affecting the base material to the nearest hundredth of a millimeter. Plating of light components without the need for masking.

Continuous Welding of B-tubes on Tubemil

Integrated high-performance welding head with a 6 kW fiber laser on the tubemil without the use of additional wire. High welding speed (up to 2 m/s) while maintaining maximum weld strength (up to 6 bar). Without consumables and additional wire during welding.

Cleaning of Oil and Operating Impurities before Painting

High-speed cleaning of heating panels embedded in fully automated painting lines. We ensure maximum adhesion of the applied varnish from all sides of the panel. Laser process takes place on the online line and includes a variable assortment size from 500x300 mm to 700x1500.

3D Laser Cleaning System C-class 2021 Platform

Automated system made for laser cleaning of welds after SMT and TIG technology before subsequent application of cataphoretic paint. The station is equipped with a 300W fiber pulse cleaning laser with a modified optical path and beam homogenization for removal of silicates, heat, oxides and grease.

Automated 3D High Speed Door Panel Cutting

Multifunctional laser robotic workstation for decorative selective removal of metallized layers with subsequent verification of the quality using deep learning. Equipped with a 70W fiber MOPA laser with a modified optical path to remove aluminium and chrome plating with minimizing heat build-up.

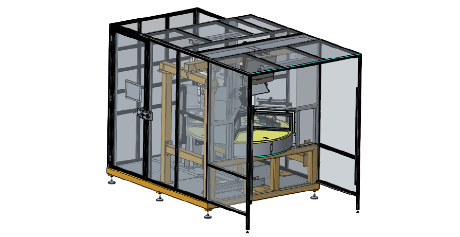

Laser Robotic Cell for Laser Cleaning of Jigs in the Online Paint shop

Closed and autonomous laser robotic cell, fully integrated into the online paint shop with customized 1000W cleaning laser with defined pulse length and energy for cleaning after the painting and aluminium plating process as a replacement for the water washer.

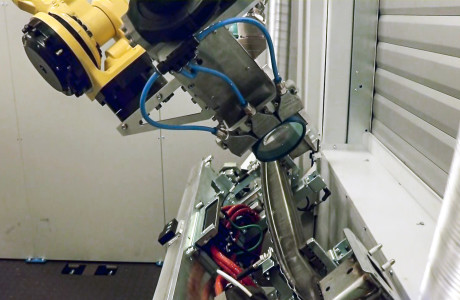

Workstation for Cutting After the On-Moulding

Multifunctional laser robotic workstation equipped with two robots with absolute accuracy calibration and two integrated laser units. The robot cuts the foil around the contour. Second robot places the part under a dynamic 3D laser with a variable focus position for mounting holes.

Robotic Laser Cell for 3D Printing

Laser robotic workstation with 9 axes combining various 3D printing technologies using powder with heated feed and cold wire with central guide via circular spot or side guide from the welding head for wobble 3D printing. Equipped with a 6000W fiber laser of the latest generation with 4 outputs.

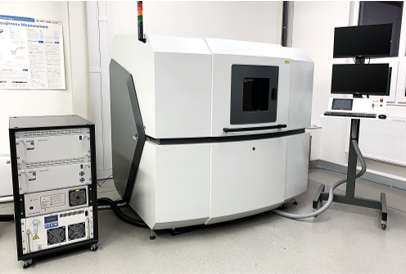

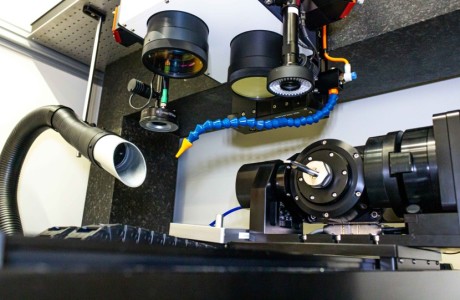

5 Axial Micromachining System with Multibeam

Synchronized micromachining system completely based on granite with accuracy ±1 µm used for processing materials, such as diamond, carbides PVD, PCB, polymers for medicine etc. Equipped with 40W femtosecond laser CARBIDE 400 µJ 1030 nm, 515 nm and 243 nm + 200W ns fiber laser MOPA.

2020 © LASCAM systems s.r.o.