ScanMaster

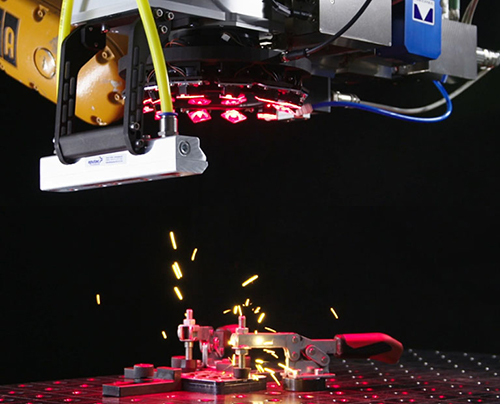

Efficient and highly productive scanner welding.

Scanner welding enables highly accurate and fast processing in series production. Using mirrors, the laser beam is positioned in the processing area without the need to move the fixed focusing optics or the workpiece. This makes machining highly dynamic, economical and efficient at the same time.

Scanner optics for remote processing not only enable precise positioning and stable processes, but also offers an attractive solution for scanner welding. It combines high-precision distance measurement to the workpiece, auto-focus, component position detection with high-resolution image processing and process monitoring. The ScanMaster has a modular design for this purpose – all performance features can be customised to individual requirements.

Strength, electrical conductivity and tightness are important criteria in the field of e-mobility. Precise, accurate and reproducible production is the focus when contacting power electronics or battery cells.

Advantages

+ Stable process with component recognition and autofocus

Fast and accurate detection of component position is essential to optimize machining time. Both the position in the X and Y axes and the working distance are essential components for a highly dynamic and reproducible process flow. The focus position can be corrected in real time across the working field.

+ Increased process reliability through intelligent online process monitoring and control

The measurement data recorded during welding is used for 100% quality control. The adjustment of the laser power is controlled in real time. Even with demanding and safety-relevant components, production errors can be detected immediately and corrected in time. This is a significant contribution to reducing rework and scrap.

With greyscale image processing, the weld seams can be viewed and the seam geometry subsequently checked.

+ Intuitive and logical data processing in one software

The versatile monitoring modules offer various data analyses of the welding process. All data is summarised in a user interface (GUI) and stored locally. In addition, parameters such as laser power, plasma, temperature and back reflection can be evaluated intuitively and clearly via touch function.

+ 100% traceability and transparency

The system is easy and intuitive to use and provides you with helpful data on your laser weld. The data storage in combination with the component ID enables consistent traceability and transparency of your laser welding processes – even after many years.

| Technical data | |||

|---|---|---|---|

| Compatibility: all IR fiber lasers

Max. laser power: 6 kW High-precision component measurement: <10 ms Dimensions: 600 x 220 x 500 mm Weight: approx. 25 kg Application examples: E-mobility, battery, battery cells, battery modules, BusBars, high-performance electronics, hairpins, fuel cells, body-in-white, seats |