Mold Cleaning

Precision mold cleaning using laser technology is an economical alternative to traditional methods. Laser mold cleaning is also a “green” process that quickly removes difficult residues without producing chemical or abrasive waste. This remarkable technique extends the service life of valuable molds that are used to form critical parts in a wide range of industries.

Precision mold cleaning using laser technology is an economical alternative to traditional methods. Laser mold cleaning is also a “green” process that quickly removes difficult residues without producing chemical or abrasive waste. This remarkable technique extends the service life of valuable molds that are used to form critical parts in a wide range of industries.

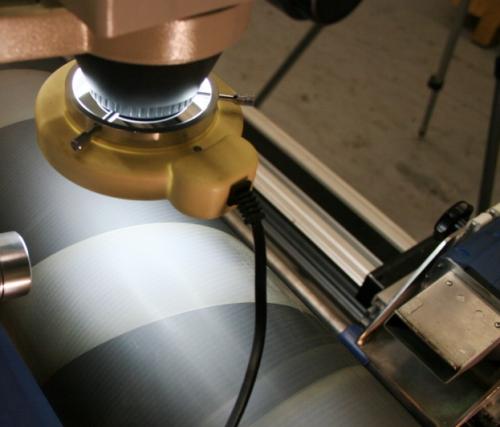

Clean-Lasersysteme GmbH has engineered unique laser systems that use the power of pulsed laser energy to eliminate stubborn release agents and process residues while being gentle enough to avoid surface damage. Through careful testing, the laser beam is precisely adjusted to optimize cleaning effectiveness in the safest manner possible for each application. Extensive research has proven laser cleaning can consistently and safely clean delicate molds, again and again. The result is significantly extended tool life.

Clean-Lasersysteme GmbH has engineered unique laser systems that use the power of pulsed laser energy to eliminate stubborn release agents and process residues while being gentle enough to avoid surface damage. Through careful testing, the laser beam is precisely adjusted to optimize cleaning effectiveness in the safest manner possible for each application. Extensive research has proven laser cleaning can consistently and safely clean delicate molds, again and again. The result is significantly extended tool life.

With laser cleaning rates up to 22 m²/hour, manufacturers can increase production by minimizing the downtime required for mold cleaning. Further, the laser process is designed to clean hot molds at ambient air temperatures up to 70°C, thereby eliminating cleaning delays during cool down.

Benefits

Benefits

- Mold cleaning rates up to 22 m²/h

- Precise consistent cleaning results

- Safely cleans without abrasion

- Extends the service life of molds

- Easy to automate

- Molds can be cleaned while hot

Do not hesitate to contact us for more information about laser cleaning.

Comments are closed.