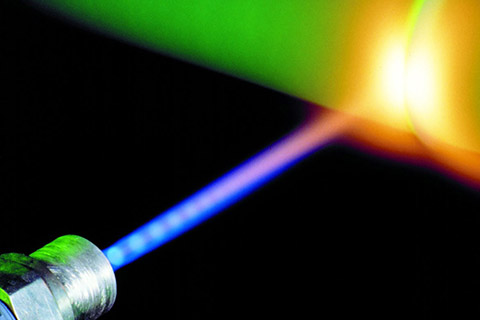

Lasers for welding

Laser welding

Compared to conventional welding processes, laser beam offers many benefits. Selective energy application within small area belongs to them. This selection results in low thermal stress and an extremely small heat-affected zone as well as extremely low distortion. This positive consequence is reflected in methodology and speed of process. Small heat-affected zone is also great precondition for welding of refinemented materials and materials with low melting point.

Pulsed Nd:YAG and fiber lasers are the most common used lasers for laser welding, these lasers are connected with 3D robotic arms thanks to lightweight portability options weld volume and spatially complex trajectory , without the multiple clamping.

Interesting application of laser welding is remote welding. The remote laser beam welding technology applies a well focused laser beam, which, by the help of quickly moving mirrors (highly dynamic galvo scanner), determine final trajectory. Because of synchronized movement of mirrors and robot axis it is possible to use heavy remote head for large-area welding with extreme high speed.

Laser welding can be applied both for metal materials (steel, copper, aluminium, bronze and platinum) as well as for polymer materials.

Advantage of laser welding:

- High process speeds translateinto short machining times (against conventional methods)

- Consistent welds

- High precision repeatability

- Laser welding dos not require additional material

- Low heat affected zone

- Welding of complicated trajectory

- Easy integration capability: laser welding can be combined with other production operations such as aligment or bending

- low consumption of active and shield gas

Contact us for more information about laser welding.

Comments are closed.