Use of industrial camera systems

Increasingly popular peripheral laser process is a monitoring system using a camera or external sensors. The requirements are often very specific and require a high degree of integration into customer solutions. Implementations of cameras and sensor also record the current trend of reducing the ” miniaturization ” or so called “down – sizing “, especially in micro-machining, drilling depth 3D material removal using ultra-short laser pulses – the goal is to machine as defined area as possible without introducing heat into the surrounding materials with online evaluation.

Specifications / Orders here Tel.: +420 778 065 205 / Email: info@lascam.cz

Processes where camera systems are applied:

- Guarded trajectory during the process of cutting or welding

- Control reading of the information and codes and their analysis

- Measurement of process parameters and their inspection

- Evaluation of distance and correct position

- Guidance during the creation and manipulation

- Machine vision

- Definition of „frame“ and „0“ process of micromachining

- Optical measurement

- Optical analysis and evaluation of the product quality

- Postprocess evaluation of the weld quality

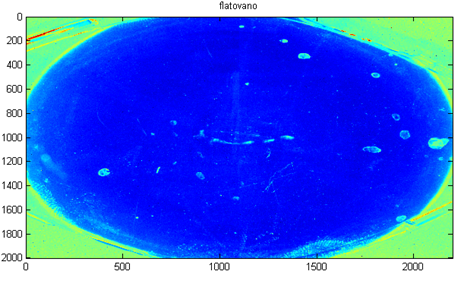

- Analysis of surface and internal defects

- Roughness measurement of the workpiece after machining etc.

Cameras also are used in applications where until now only a subjective human evaluation was used:

- Analysis of the molds quality in Automotive sector

- Analysis of the internal and surface defects of transparent optical components

- Analysis of defects in process such as TIG/MIG welding

More information here.

Do not hesitate to contact us for more information about industrial camera systems.

Comments are closed.