Check out suppliers of laser cleaning technology

Laser cleaning is currently a big hit in the field of industrial cleaning. Many companies consider buying this technology, but they don’t always reach the right supplier that understands the technology and knows what is suitable for the customer.

Laser cleans variety of surfaces and can replace other technologies such as dry-ice cleaning or blasting. It can even clean surfaces that can not be treated with standard technologies. But it is necessary to buy laser technologies from verified suppliers with high-quality references, where you get laser tailored just for you thanks to the advice of experts. Suppliers, who don’t understand lasers and sell almost anything to the customer, are a very bad advertising for laser cleaning technology. In most cases, it results in the demotion of the technology and material damage to the customer property.

Laser cleans variety of surfaces and can replace other technologies such as dry-ice cleaning or blasting. It can even clean surfaces that can not be treated with standard technologies. But it is necessary to buy laser technologies from verified suppliers with high-quality references, where you get laser tailored just for you thanks to the advice of experts. Suppliers, who don’t understand lasers and sell almost anything to the customer, are a very bad advertising for laser cleaning technology. In most cases, it results in the demotion of the technology and material damage to the customer property.

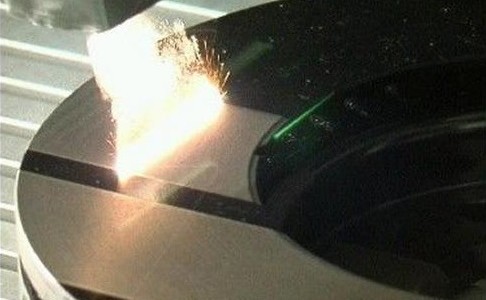

Acquisition of laser cleaning technology can look easily. However, component selection and adjustment, requires extensive knowledge from optics, metallography and material absorption. Quality of the cleaning doesn’t determine only the laser power, but especially the frequency, pulse duration, spot size, power distribution to the surface and effective overlap of individual points.

Acquisition of laser cleaning technology can look easily. However, component selection and adjustment, requires extensive knowledge from optics, metallography and material absorption. Quality of the cleaning doesn’t determine only the laser power, but especially the frequency, pulse duration, spot size, power distribution to the surface and effective overlap of individual points.

Tips on how to easily tell whether they are experienced professionals:

- Ask for the right laser power and type! Why? You’ll never clean mold for plastics with 20W or 50W laser without destroying it

- Laser cleans polished surfaces to a mirror shine – but you must know how to adjust parameters of the process

- Power of the laser source doesn’t automatically means better results – for example welds can be best cleaned with the power of 50 W, where there is no reoxidation

- Ask for references – “Do you have references from customers who are already using this technology, or at least videos that demonstrate use of the technology?”

- Fumes are generated during cleaning process – ask for their filtration and separation

- The process requires a special laser safety – you endanger yourself without laser protection!

- The laser is not for everything – optimal are metal surfaces with deposits to 250um

- Laser can clean plastics – yes, but check the laser power and type of plastics

Laser cleaning technology has a wide range of applications in various fields of industry. Beware the correct selection and parameterization of the laser equipment at the beginning, otherwise your investment in a new laser can be significantly more expensive.

Your LASCAM team

Do not hesitate to contact us for more information.

Comments are closed.