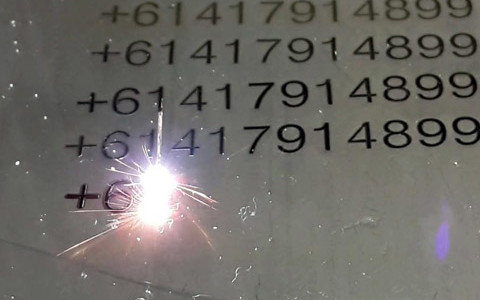

Lasers for marking / engraving

Laser marking / engraving

Flexibility, versatility, precision and speed – all the of cited benefits and properties of industrial materials processing with lasers can be seen in laser marking.

Fiber lasers are usually used for marking high-quality stock, CO2 lasers are frequently used on mass-produced articles. These lasers are mounted on stationary shoulder or 2-axis plotter. Favourite application is using of galvoscanner – scanning optics have two movable mirrors that deflect the laser beam and is able to mark very fast with same position but bigger area. Combination of galvoscanner and robotic arm determine these process for marking of three-dimensional workpiece. This non-contact process guarantee reproducibility in assembly-line production.

For non-metal material, because of low reflectance and high absorption, it is suitable used CO2 lasers (10.6 um wavelength). For metal materials is suitable used lasers with wavelength 1.068 um.

Advantage of laser marking:

- Fast and easy integration

- High accuracy of repeated cycle

- High productivity

- Quick return of investment

- Non-contact methode

- Environmentally friendly process

- Long lifetime of technology up to 100 000h

- Almost zero heat affected zone

Contact us for more information about laser marking / engraving.

Comments are closed.