Lasers for drilling

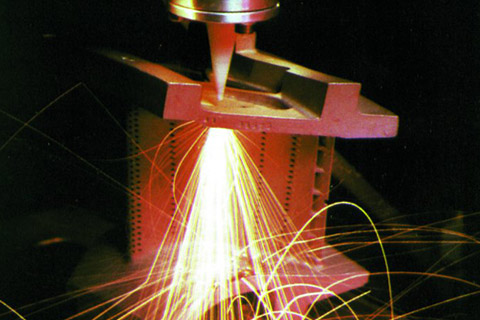

Laser drilling

In laser drilling, a short laser pulse with high power density feeds energy into the workpiece extremely quickly, causing the material to melt and vaporize. The greater the pulse energy is, the more material is melted and vaporized. Vaporization causes the material volume in the drilled hole to increase suddenly, creating high pressure. The vapour pressure expels the molten material from the hole. For laser drilling pulsed, fiber or Nd:YAG sources are often used with shorter wavelength (335 nm or 532 nm) – better absorption in materials.

Over the years, several drilling processes developed from the basic method:

Single-shot and percussion – in the simplest case, a single laser pulse with comparatively high pulse energy is used to produce the hole. In percussion drilling, the hole is produced using multi short-duration, low-energy pulses. This technique produces deeper, more precise holes and also enables smaller hole diameters.

Trepanning – In this process, a pilot hole is first created using percussion drilling and then laser enlarges the pilot hole, moving over the workpiece in a series of increasingly larger circles.

Helical drilling – The laser begins moving in circles over the material as the pulses are delivered, with a large amount of material shooting upward in the process. The laser continues to work its way through the hole in a downward spiral. Helical drilling makes it possible to produce very large and deep high-quality holes.

Advantage of laser drilling:

- Very precise accuracy of holes

- High speed process

- Easy integration

- Low heat affected zone of the material

- Non-contact method

- Stable reproducibility

- Long lasting technology

Contact us for more information about laser drilling.

Comments are closed.