Pre-Treatment for Adhesive Bonding and Coating

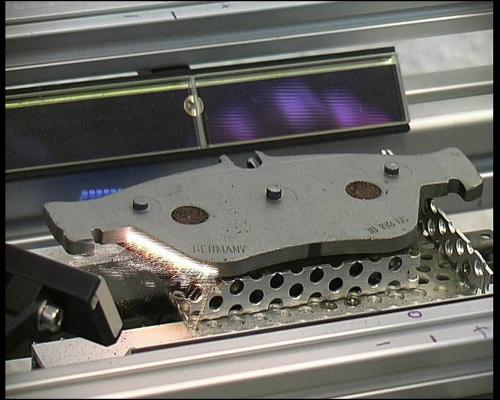

Cleaning and pre-treatment of the surface is an important prerequisite for a high-quality adhesive bond area. In the laser process only dirt particles, oxide layers and other contaminations are vaporized by bundled light only.

Cleaning and pre-treatment of the surface is an important prerequisite for a high-quality adhesive bond area. In the laser process only dirt particles, oxide layers and other contaminations are vaporized by bundled light only.

Laser pre-treatment leaves the metallic surface free of contamination and well prepared for bonding. The substrate is not damaged by the laser light. Metallic materials can be “modified” within the upper boundary layer using appropriately intensified laser parameters. This means the surface of the substrate can be enlarged respectively, modified to match the bonding mechanisms.

By targeted modification of the surface, the corrosion behavior of light alloys can be improved significantly. The substrate is resistant to age and environmental damage.

Further benefits compared to conventional technology:

Low running costs (usually less than 1 €/hr.)

Low running costs (usually less than 1 €/hr.)- No consumable media and abrasives

- Low space requirements

- Easy automation and in-line integration

- Precise cleaning of partial areas: only the required areas need to be cleaned

- Environmentally friendly process with energy savings of up to 87%, awarded with

Do not hesitate to contact us for more information about laser cleaning.

Comments are closed.